Mining Land Displacement Monitoring Using SAR

Enhancing Mine Safety and Stability Through High-Resolution DTM

Mining activities inherently alter the natural terrain, making land displacement monitoring a critical requirement for safe and sustainable operations. Ground subsidence, slope instability, pit wall failure, and overburden movement pose significant risks to mining assets, worker safety, and surrounding communities. As mining operations expand in scale and complexity, traditional ground-based monitoring alone is no longer sufficient. This is where SAR-based mining land displacement monitoring integrated with high-resolution Digital Terrain Models (DTM) plays a vital role.

At SATPALDA, we deliver advanced Synthetic Aperture Radar (SAR)–based land displacement monitoring solutions combined with accurate DTM generation to support proactive risk management, regulatory compliance, and long-term mine stability planning.

Why SAR Is Ideal for Mining Areas

Synthetic Aperture Radar (SAR) is uniquely suited for mining environments due to its all-weather, day-and-night imaging capability. Unlike optical satellite imagery, SAR is unaffected by cloud cover, dust, smoke, or haze—conditions commonly present in active mining regions.

One of SAR’s most powerful capabilities is Interferometric SAR (InSAR), which enables the detection of millimetre-scale ground deformation over time. This level of precision allows mining operators to identify subtle terrain movement long before visible signs of failure occur.

Key advantages of SAR for mining land displacement monitoring include:

Continuous monitoring of active and abandoned mines

Reliable data acquisition in remote and inaccessible locations

Detection of slow-moving deformation patterns invisible to ground inspections

Large-area coverage across extensive mining leases

By using satellite-based SAR data, mining stakeholders gain a consistent and scalable monitoring solution that reduces dependency on manual field surveys.

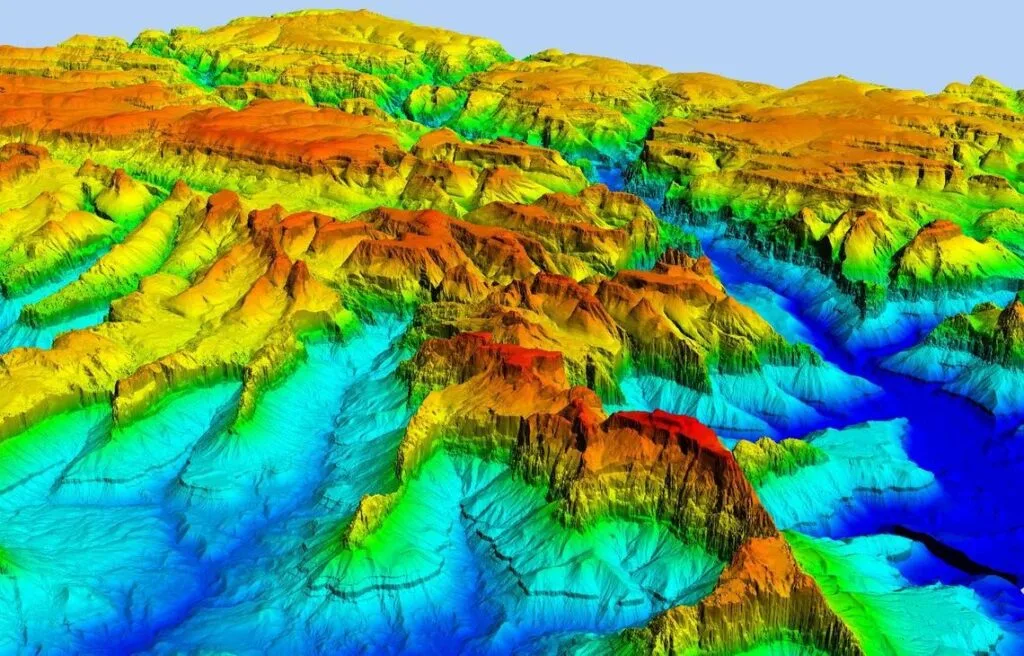

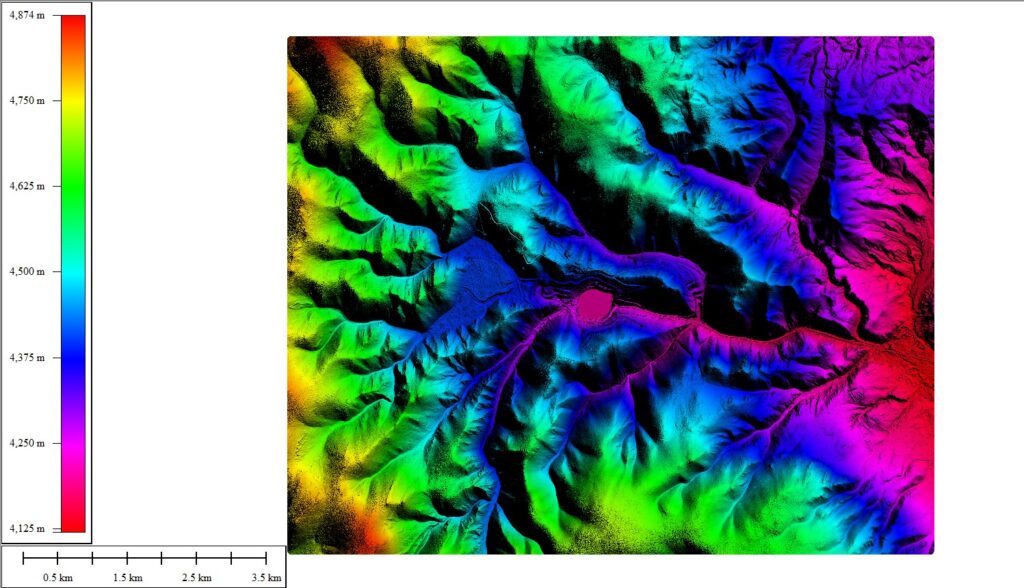

Importance of High-Resolution DTM in Mining Displacement Analysis

A Digital Terrain Model (DTM) represents the bare-earth surface after removing vegetation, buildings, and other surface features. In mining applications, high-resolution DTM data is essential for understanding true terrain behavior and accurately interpreting deformation signals.

The DTM integrated within SATPALDA’s SAR monitoring workflow enables:

Accurate representation of pit geometry, benches, dumps, and haul roads

Detailed analysis of slope angles, elevation gradients, and drainage patterns

Terrain correction of SAR-derived deformation maps

Identification of high-risk zones prone to subsidence or slope failure

When SAR deformation data is combined with a high-quality DTM, mining engineers can distinguish between apparent movement caused by topography and actual ground displacement. This integration significantly improves the reliability of mine-specific displacement assessments.

Key Mining Applications of SAR–DTM Monitoring

SATPALDA’s integrated SAR and DTM-based mining monitoring solutions support a wide range of applications across the mining lifecycle:

Open-cast mines: Early detection of pit wall movement, bench instability, and slope deformation

Underground mines: Identification of surface subsidence zones linked to underground voids

Overburden and waste dumps: Monitoring settlement, slope creep, and dump stability

Mining infrastructure: Stability assessment of haul roads, processing plants, tailings facilities, and nearby settlements

These insights enable operators to implement preventive measures before minor deformation escalates into operational disruptions or safety incidents.

Benefits for Mining Operators and Regulators

For mining operators, SAR-based land displacement monitoring offers measurable operational and financial benefits. Large mining leases can be monitored consistently without installing dense networks of ground-based instruments. This reduces costs while improving spatial coverage and data continuity.

Regulatory authorities benefit from independent, satellite-derived monitoring data that supports compliance verification, environmental oversight, and risk-based decision-making.

Key benefits include:

Scalable monitoring across large and complex mining areas

Reduced reliance on ground instrumentation

Early-warning capability for proactive intervention

Improved safety, asset protection, and environmental compliance

SATPALDA Value Proposition

SATPALDA brings together advanced SAR processing, high-resolution DTM generation, and GIS-based analytics within a single operational framework. Our solutions deliver GIS-ready outputs, technical reports, and visual products that integrate seamlessly into existing mine planning and monitoring systems.

Our SAR–DTM monitoring solutions are applicable across coal, metal, and mineral mining sectors, supporting both operational safety and long-term sustainability goals.

By integrating SAR and DTM technologies, SATPALDA enables mining stakeholders to move from reactive inspections to predictive, data-driven mine stability management, strengthening resilience and decision confidence across mining operations.

Dr. Deepak Kumar Raj

Product Specialist